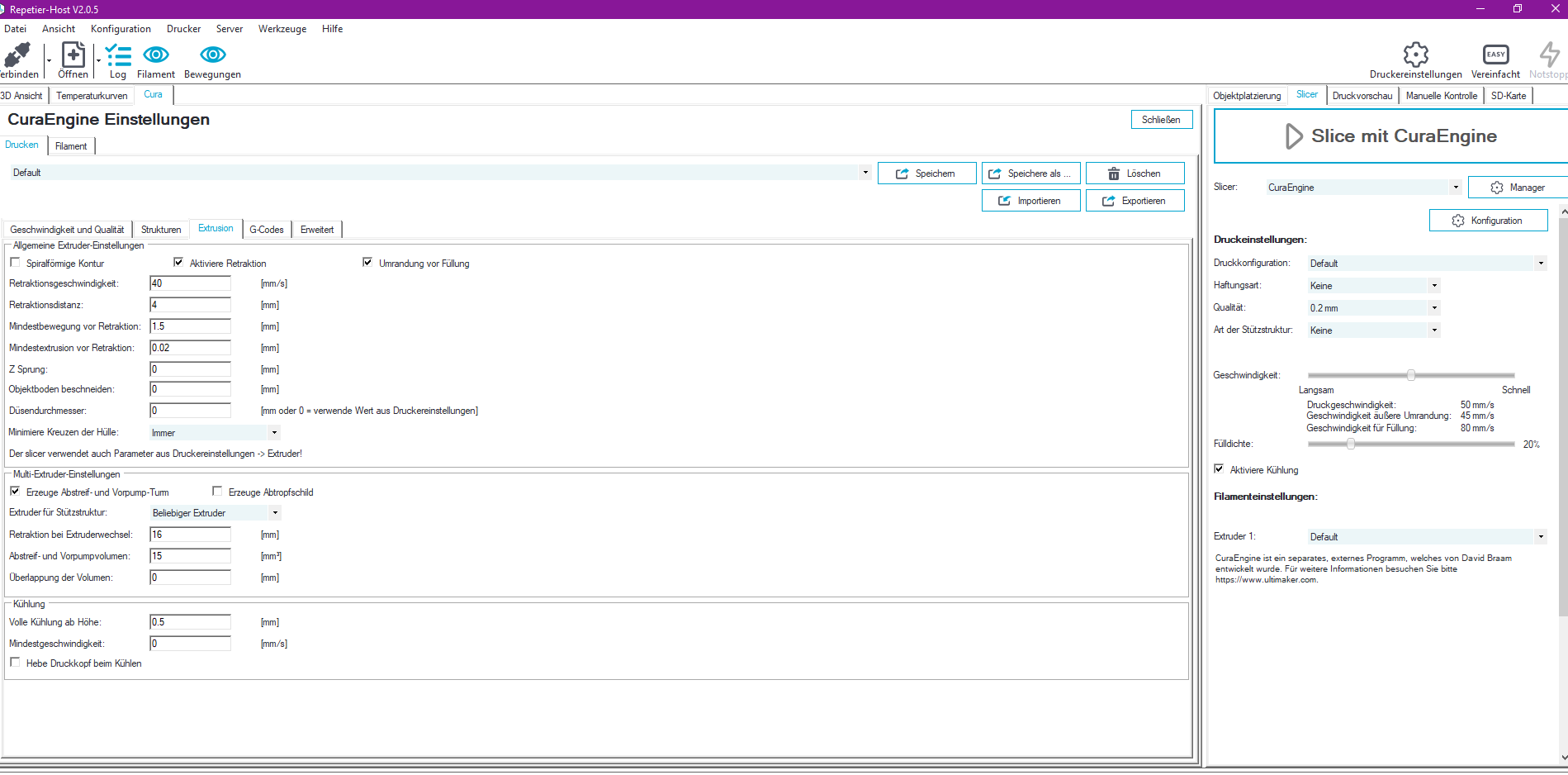

We then hone in the retraction settings for ABS.

Our standard quality print settings are at a. 1mm layer heights will take twice as long as one at .2mm, so these factors are important to consider. We run our ABS settings for quality extremely similar to PLA (in case you had already read our PLA Settings guide). The layer height of your print is very dependent on the nozzle size of your printer as well as the quality of the print you would like. Environmental conditions and filament origin can heavily impact these settings as well*** When using Simplify 3D we use very similar profiles. We have used these settings on our TAZ3 and TAZ5 printers with HATCHBOX and E-Sun 3.0mm ABS with success. ***Disclaimer: The following ABS settings are for Cura and work well on Lulzbot TAZ printers with an E3D hotend. Since ABS has a high shrinkage rate which causes warping, we will only print larger ABS jobs with our proprietary enclosure or on our fully enclosed 3D printer.ĪBS also allows for the ability to post process using acetone vapor finishing, something we always suggest doing to enhance the strength and look of ABS parts.

The problem arises when printing large parts. Small items are quite easy, and the printer can handle ABS without any issues. This is our second profile tutorial and today we will be taking a look at the settings and profiles that have worked for us while printing in ABS.įurther than just explaining preferred temperature settings, we will be taking an indepth look at advanced support and infill settings, as well as many other factors that go into making a clean and successful print.ĪBS is quite unique to PLA for a few reasons.

#Hemera retraction settings trial

Through trial and error we have slowly honed in our profile settings for different 3D printing materials.

0 kommentar(er)

0 kommentar(er)